Geneva devices link adjacent digit wheels of Miles. The devices cause 9-to-0 transitions of a digit wheel to advance the wheel on its left by one position. For instance when counting from 19 to 20, the digit wheel that represents the units position advances from 9 to 0. Then through the Geneva device, the digit wheel that represents the tens position advances from 1 to 2. A Geneva device is based on an ordinary spur gear, and so I need to define a spur gear.

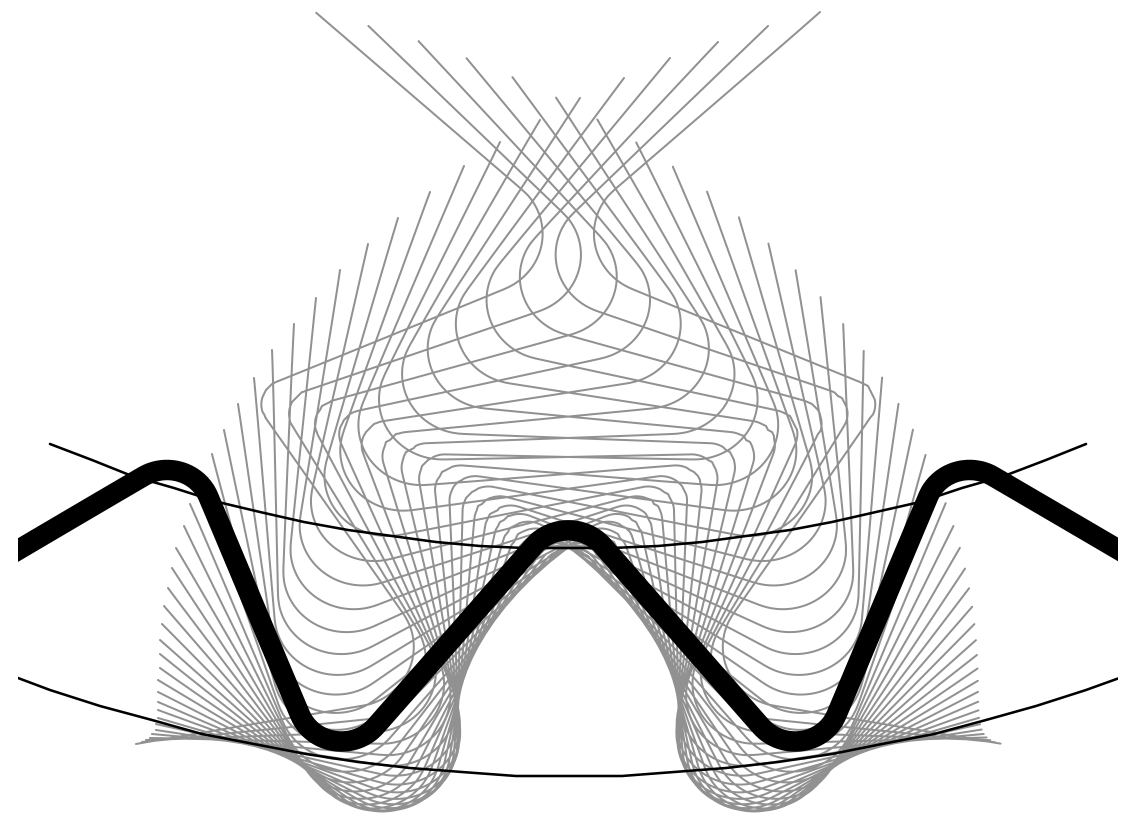

The shape of a spur gear is implied by the digit wheel’s wire gear. The image below shows a 20-tooth wire gear rotating around the location of a spur gear. This isn’t the actual motion of gears in Miles, all of which rotate on fixed shafts. But by keeping the spur gear motionless in this image, the movement of the wire gear defines the spur gear’s shape.

Focus on a single tooth of the spur gear, which is implied by the white area below the wire in the image below. This white area is the place that the wire gear never goes. You’ll notice that in the image, the gears do not quite touch. The tooth of the spur gear has been shrunk slightly to ensure separation from the wire gear and to prevent binding. I can replicated this tooth shape eight times and define the spur gear.

Spur gears are defined to allow a slight separation between wire gears and spur gears to prevent binding.

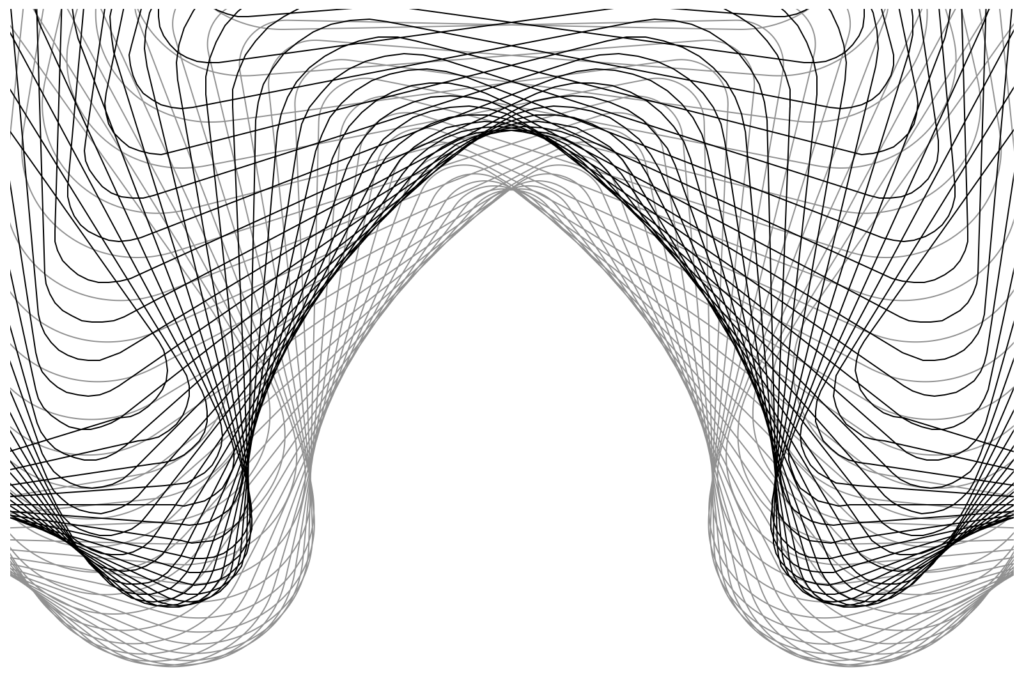

Actually, since the spur gear will be created on a CNC milling machine, I really need the path of the 0.5-inch end mill. Such a path will be 0.25 inch outside the tooth’s shape and can be created using the same technique, but with an artifically altered wire-gear shape. The darker lines in the plot below imply the path that the center of a 0.5-inch end mill should follow to make a tooth of the spur gear. The end mill does not need to follow every dark line in the plot; it just needs to follow the portions of the dark lines that are closest to the tooth.

Lighter lines show the outline of a tooth of a spur gear. Darker lines imply the path that the center of a 0.5-inch end mill should follow to cut the tooth of the gear.