With all of the talk about tests, it’s time to start planning them.

Edge Strength

I’d like to use ripped 2×4’s instead of 3/4″ EMT conduit or 2″ PVC tubing because 2×4’s are less expensive. My hypothesis is that ripped 2×4’s are stronger than 2″ PVC and 3/4″ EMT.

To test my hypothesis, I’m going to bend each of these three materials until they break, measuring the maximum amount of bending force that they withstand.

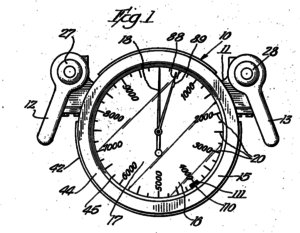

Fortunately, I have a Dillon Dynamometer, which is a device that is used to measure tension in cables or ropes. Mine has a capacity of 1,000 pounds, which is sufficient to break any of these materials.

Fortunately, I have a Dillon Dynamometer, which is a device that is used to measure tension in cables or ropes. Mine has a capacity of 1,000 pounds, which is sufficient to break any of these materials.

My idea is to suspend each material by its ends using rope, with the Dillon Dynamometer measuring the tension in one of the ropes, and then step on the item midway between the suspension points, increasing downward pressure until the item breaks. The Dillon Dynamometer records the maximum tension that was in the rope.

After data collection, I can use the recorded maximum tension in the rope for each material as a proxy for the material’s strength.

Fabric UV Protection

I have a gazillion kinds of cover materials to choose from, and I’d like to know their relative abilities at shielding from UV light. Clothing uses a value called “UPF” to indicate the UV protection factor of the garment. UPF is the reciprocal of UV transmission, and so a UPF of 25 means that 1/25th of the UV is being transmitted.

My idea is measure the UV transmittivity of each material using a Tanita UV-Smart UVA/UVB dosimeter. The dosimeter reports radiation in W/m², and so I just need to go outside at noontime on a sunny day and measure the UVA and UVB of the direct sunlight both with and without shielding from various fabrics.

My idea is measure the UV transmittivity of each material using a Tanita UV-Smart UVA/UVB dosimeter. The dosimeter reports radiation in W/m², and so I just need to go outside at noontime on a sunny day and measure the UVA and UVB of the direct sunlight both with and without shielding from various fabrics.

Cover Fabric Burst Strength

Burst strength is the ability of a fabric to withstand a tear due to stretching. A poor-man’s burst test goes like this:

Clamp a piece of fabric between two large washers using several C clamps. Then, using a 1″ steel ball, push the ball through the hole in the washers until the fabric ruptures. Measure the maximum amount of force needed to “burst” the fabric.

Although this test isn’t calibrated, it can be used for relative measurements.

Some innovation is needed to measure the maximum amount of force that is applied to the steel ball. One way uses the Dillon Dynamometer in a lever arrangment. Another way is to place a bathroom scale on a platform that is supported by the steel ball, and then increase the amount of material placed on the scale until the fabric fails. The reading on the bathroom scale, plus its own weight and that of the platform, is the force applied.

Cover Fabric Water Resistance

There’s a hypothesis that a dense fabric at an angle will not let water through. I’d like to test that idea with the fabric samples. Then I’ll know whether an interior tarp or canvas will be needed.

Cover Fabric Fade Resistance

Gold Lamé isn’t intended to be used outdoors, and so I’d like to test how it holds up.

Update: January 9, 2005

Shade cloth manufacturers specify their products’ light transmission as a percent. There is an implied assumption that the light spectrum affected is in the photosynthetically active region (400 nm to 700 nm, or visible light). Unless otherwise specified, the filtering of the UV spectrum may be different. For instance, fluorescent colors convert UV light into visible light, and so fluorescent colored shade cloth, or even white, may filter UV light more than visible light. “Brighteners” in clothes detergents are dyes that do that conversion.

More reading on different colors of shade cloth suggests that black cloth causes about 4 degrees of heating in greenhouses compared to silver cloth. In addition to measuring UV, I will measure the amount of transmitted IR radiation. To round things out, I probably should measure transmitted light in the visible spectrum, too. I’ll need to find a meter for that.

So the spectra that I will measure are: UVB (280-320 nm), UVA (320-400 nm), visible (400-700nm), and infrared (by measuring the temperature rise of the fabric in the sun compared to air temperature).

Update: January 27, 2005

The maximum elevation of the sun at Burningman on August 29, 2005, is 58 degrees. At my house, the maximumelevation will be the same on April 4, 2005. The altitudes are slightly different, however. Burning Man is at 3900 feet, while my house is at 2500 feet. I’ve heard that at 1000-m altitude, the intensity of UVB is 15% higher than it is at sea level. Also said to be 20% stronger for every 5000-ft of altitude. Another source says 10% for every 1000-ft in altitude. And another source says 3% for every 1000-ft altitude. UVA is said to be unaffected.

Update: February 26, 2005

I’ve just discovered that Mount Hamilton’s Lick Observatory is about the same altitude as the Burning Man site. Perhaps I should make a UV measurement on Mt. Hamilton at noon on Sunday, April 3.